Your cart is currently empty!

Decoding Aerospace Part Numbers: AN, MS, and NAS Standards

Decoding Part Numbers: AN, MS, and NAS Standards

Understanding aerospace part numbers can seem daunting, but these alphanumeric codes are meticulously designed to convey vital details. In this post, we’ll explore the AN (Army-Navy), MS (Military Standard), and NAS (National Aerospace Standards) systems and how learning their structures can simplify component selection. We’ll also give a quick example of how some part numbers indicate a second part number for proper usage, using Hi-Lok (HL) fasteners.

Why Understanding Part Numbers Matters

Did you know that a single misidentified fastener can delay aircraft repairs by days, costing thousands in downtime? In aerospace, using the correct part is not just a matter of efficiency—it’s critical for safety and regulatory compliance.

By understanding part numbers, you can:

- Reduce maintenance time by quickly identifying compatible parts.

- Ensure safety by selecting the right materials and specifications.

- Maintain compliance with industry standards like FAA or EASA regulations.

AN Standard: The Foundation

AN parts, developed during World War II, standardized hardware specifications across military aircraft. They include bolts, nuts, and other fasteners with clear, descriptive part numbers.

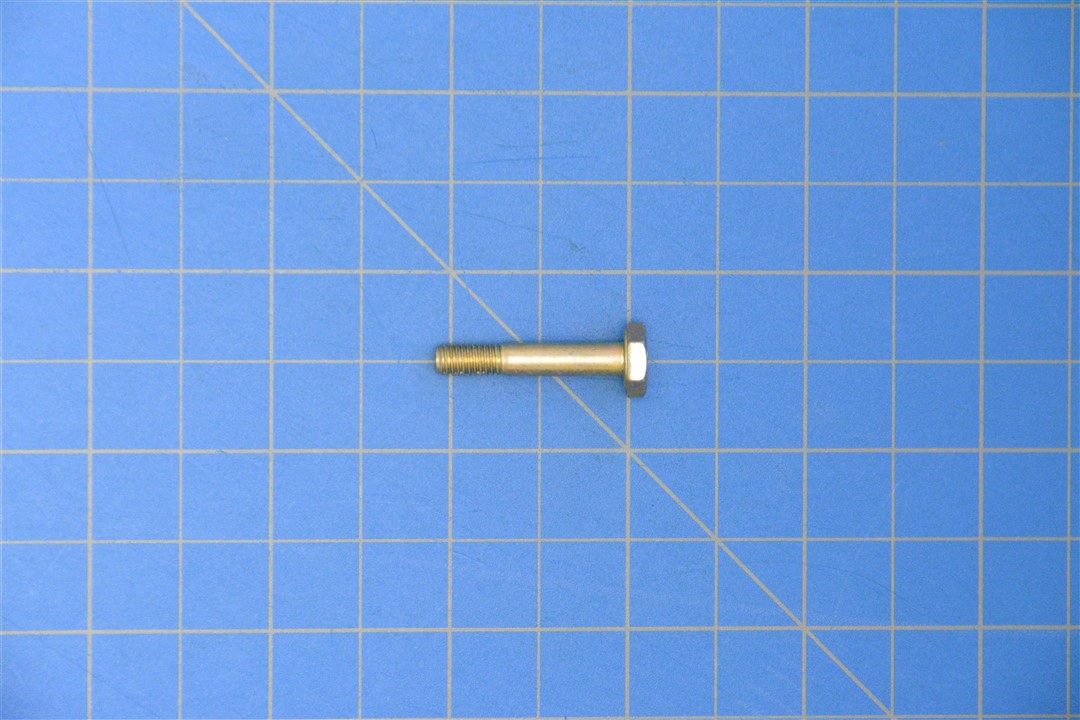

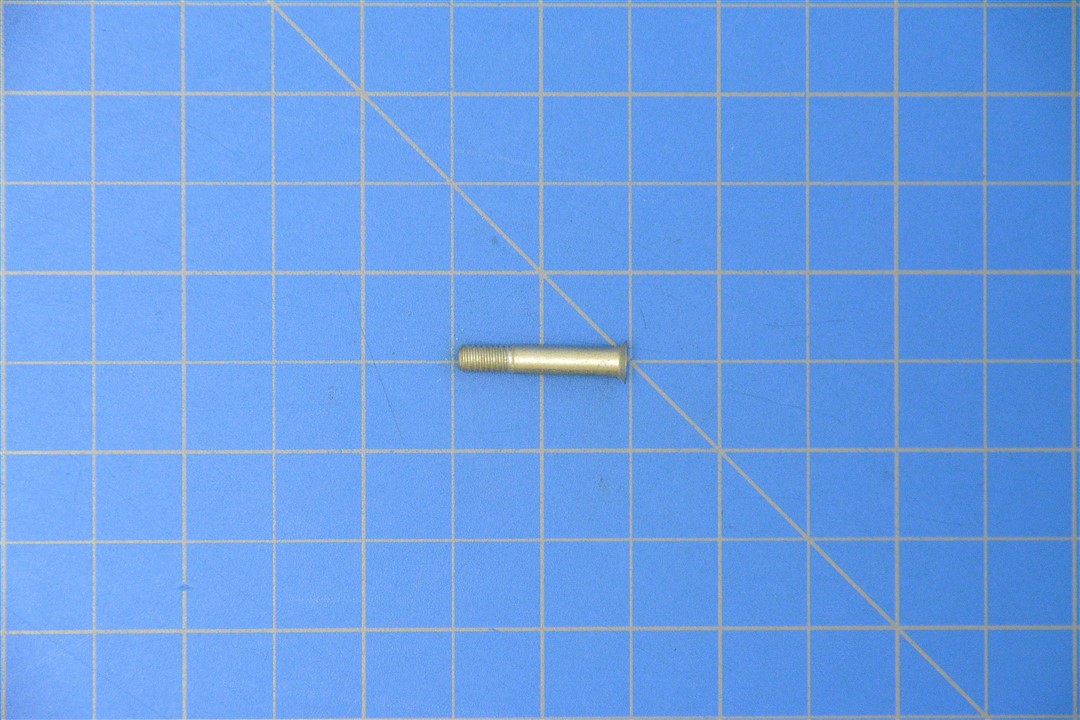

Decoding AN3 Bolts: What the Numbers Mean

In AN3 bolts, each number in the part designation provides vital information about the bolt’s specifications. Understanding these details ensures you select the correct fastener for your application, whether you’re working on an aircraft’s structural components or other critical assemblies.

The first number after the AN prefix, in this case, 3, refers to the bolt’s nominal diameter. This number represents the diameter in 1/16-inch increments.

For AN3 bolts:

- 3 × 1/16 inch = 3/16 inch (or 0.1875 inches).

Thus, the diameter of an AN3 bolt is 3/16 inch. This ensures the bolt fits snugly in pre-drilled holes, providing the necessary load-bearing capacity and minimizing movement within the joint.

The number following the dash, such as -10 in AN3-10A, indicates the grip length of the bolt. Like the diameter, this is also measured in 1/16-inch increments.

For AN3-10A:

- -10 means 10 increments of 1/16 inch.

- 10 × 1/16 inch = 10/16 inch = 5/8 inch.

The grip length refers to the unthreaded portion of the bolt, designed to pass through the material being fastened without engaging the threads. This ensures the load is borne by the bolt’s shank, maximizing joint strength and preventing thread damage.

| Part Number | AN3-10A |

| Diameter | 3/16" |

| Thread Class | 3A |

| Surface Treatment | Cadmium and chromate |

| Material | Steel |

| Head Style | Hexagon |

| Grip Length | 5/8" |

| Thread Qty Per Inch | 32 |

| Thread Series Designator | UNF (Unified Fine Thread) |

MS Parts and NAS Parts

As aerospace technology advanced, MS parts were introduced to enhance AN standards with stricter tolerances and improved materials. These parts often have direct AN equivalents, making them interchangeable in many cases.

| AN Part | Equivalent MS Part |

|---|---|

| AN73 | MS20073 |

| AN310 | MS21042 |

| AN364 | MS20364 |

For example, the AN73 series bolt was superseded by MS20073. Both parts maintain similar strength and dimensions but adhere to more rigorous modern standards.

For instance, NAS464 bolts are frequently used in engine mounts and landing gear assemblies, where high tensile strength is crucial.

NAS parts cater to the unique demands of advanced aerospace systems, often offering higher precision and strength than their AN or MS counterparts. Despite their differences, many NAS parts share specifications with MS standards.

| NAS Part | Equivalent MS Part |

|---|---|

| NAS464 | MS21250 |

| NAS679 | MS21042 |

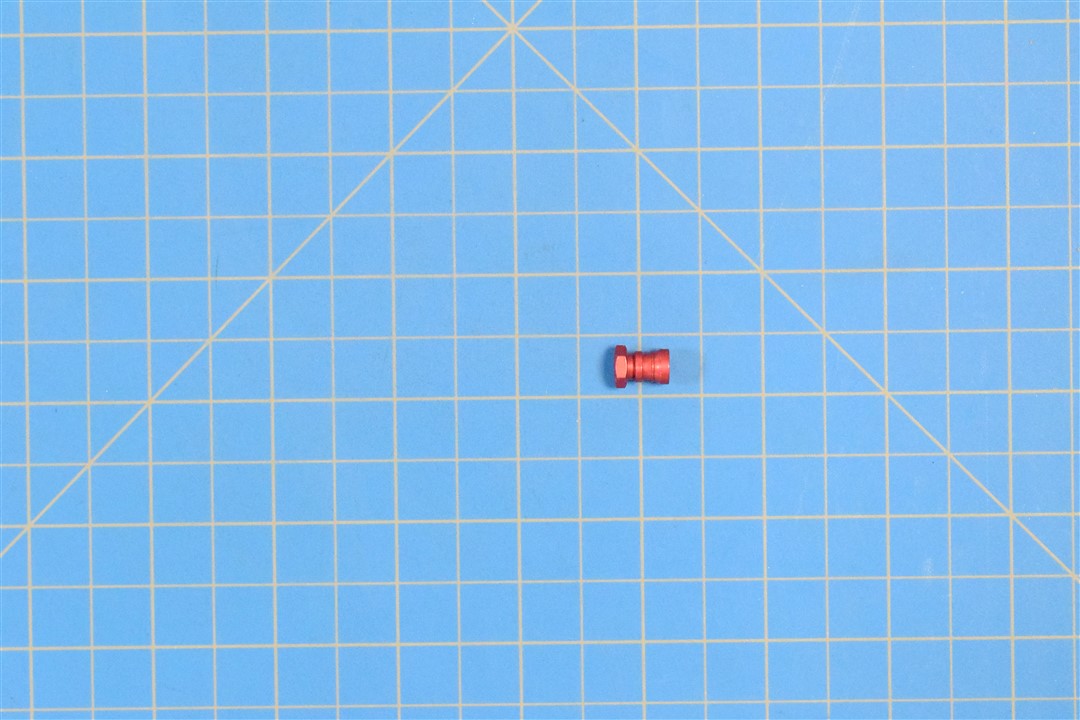

HL Parts: Pin and Collar Systems

Hi-Lok fasteners, such as HL19PB5-10, are widely used in modern aircraft due to their strength and ease of installation. Each part number provides detailed information about its specifications:

- HL19: Hi-Lok pin rivet series.

- P: Cadmium-plated steel material.

- B: Button head, ideal for low-profile applications.

- 5: Diameter of 5/32 inch.

- -10: Grip length of 1.0 inch.

These fasteners work as a system, where the 5 indicates the required collar diameter. Pair this pin with an HL70-5 collar for a perfect fit. This pairing reduces installation errors and ensures optimal joint strength, making Hi-Lok fasteners a favorite for fuselage and wing assemblies.

Comparison of Standards

Here’s a quick overview of how these systems differ:

| Feature | AN | MS | NAS |

|---|---|---|---|

| Primary Use | General aviation | Military/commercial | High-precision needs |

| Material Options | Standard | Enhanced | Advanced alloys |

| Strength | Moderate | High | Very high |

Real-World Applications

- AN Parts: Commonly found in general aviation aircraft, especially older models.

- MS Parts: Used in both military and commercial aircraft, offering improved durability.

- NAS Parts: Critical for components under high stress, such as landing gear or engine mounts.

- HL Parts: Ideal for aerodynamic assemblies, reducing drag while maintaining structural integrity.

Practical Tips

- Use a Part Number Catalog: Reference tools like Skybolt’s catalog to cross-check part numbers quickly.

- Keep Compatibility Charts Handy: Save time by knowing which AN, MS, and NAS parts are interchangeable.

- Consult Maintenance Manuals: Always verify part numbers against your aircraft’s repair manual to ensure proper installation.

Conclusion

While aerospace part numbers may seem complex, understanding their structure and purpose is key to ensuring the right components are used. It’s impossible to know every detail offhand, but with the right resources and a solid grasp of the basics, you can confidently select parts that guarantee safety, reliability, and compliance in any project.

Leave a Reply

You must be logged in to post a comment.